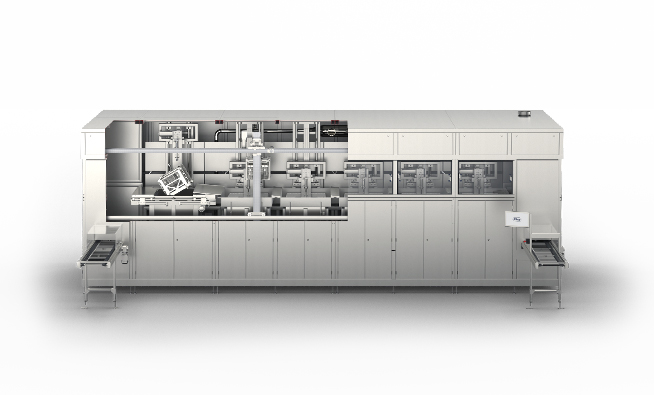

Elmasystem Neo

Ultrasonic Cleaning Systems: Innovativ. Customer-oriented. Modular.

Individuality and standardization are not mutually exclusive with project related Elmasystem Neo cleaning systems.

Parts or components have their own specific requirements with regard to the necessary filmic and particular cleanliness for the subsequent application and function.

As a specialist and system solution provider for fine and ultra-fine cleaning, our experts from Elma application laboratory, technical sales and project planning will be happy to assist you with individual guidance and implementation.

We offer individual systems and process concepts for your requirements:

- Systems for aqueous, semi-aqueous and solvent processes (ATEX systems)

- Ultrasonic in multi-frequency technology in various versions

- Movement of cleaning parts with oscillation, rotation horizontally or vertical

- Individual design of the process stations for cleaning and rinsing steps

- Drying systems such as hot air, hot air with HEPA filter, infrared, vacuum or vacuum in combination with additional hot air or infrared

- Handling system with single or multi-transport robot, multiple converter or lift and push technology

- Laminar flow technology for clean room application

- Bath care units such as filter pump units, under water floods, oil separator, chemical dosing devices

- Pure water treatment systems

- Rinse water treatment plants

- Concept to reduce rinsing water consumption through conductivity-controlled volume flow

- Integrated online measuring systems like conductivity, pH- value TOC, particles, density

- System control by IPC technology for the integration and connection of barcode scanner, RFID system, data logger, audit trail and other software modules, as well as communication with frontend and backend production machines by existing OPC-UA, MES or IT systems