Qualification and re-qualification of ultrasonic devices

to verify the ultrasonic performance as part of process validation

Product quality and effective production are becoming increasingly important. After all, our customers also want to produce quality products continuously. With validated processes, you can always compare and check all production steps, procedures and methods with the specified requirements.

The qualification of ultrasonic devices serves the quantitative evaluation of parameters which are directly or indirectly relevant for the cleaning performance of the device. It enables the integration of the ultrasonic devices into existing, validated processes.

Advantages of the (re-)qualification:

- Integration of ultrasonic cleaning devices in validated processes

- Ensuring the required cleaning performance

- Verification of the required product quality

What parameters are evaluated when qualifying my ultrasonic device?

The following parameters are evaluated:

- Cavitation noise level according to the standardised acoustic procedure IEC TS 63001:2019

- Ultrasonic functions sweep and pulse

- Bath temperature and heating curve

- Technical and mechanical properties (evaluation of ultrasonic tank, electrical connections, drain, etc.)

Why should I have my ultrasonic device requalified?

All parameters of the initial qualification are measured again at Elma, documented in a checklist and current test certificates issued again.

- Re-qualifications take place cyclically at regular intervals (e.g. annually)

- Declining device performance can thus be detected and rectified at an early stage

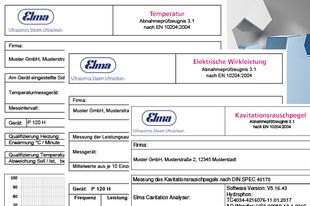

The qualification of your ultrasonic device comprises three test certificates:

- for cavitation noise level

- for power consumption

- for bath temperature / heating curve.

The procedure - the cavimeter test

We developed the acoustic procedure for qualification and re-qualification - the cavimeter test - in order to check performance-relevant parameters of ultrasonic devices.

On request, both the initial qualification and the re-qualification can be carried out under specific process conditions defined by you or under the standard parameters defined by Elma.

When purchasing an ultrasonic unit, you can have it qualified before delivery at a charge. The device test certificates for all tested parameters are then also provided. Existing devices are re-qualified at our premises or on request and, under certain conditions, also at your premises.

This allows you to ensure and prove that the original characteristics and performance of your device are still present.

Fascination Cavitation | The wonderful world of ultrasonic cleaning

The Elma ultrasonic magazine

Dive beneath the surface of the ultrasonic bath and enter the wonderful world of ultrasonic cleaning. Our Principal Engineer David Holly and author of the Elma ultrasonic magazine explains the technology step by step. He explains in an easily understandable way what exactly makes cavitation so fascinating and how it works. Below you will find a short reading sample - we will be happy to send you the Elma ultrasonic magazine in digital form.